Its time to call in for some advice because I'm running out of ideas..........I bought a real clean QT8N with T Plus control from a Vo-Tech that absolutely looks new, it was in storage for 7 years while their machining program was closed and once they restarted the program in the new facility they reinstalled it, they had problems with it and they couldn't seam to get it fixed so they sold it at auction.

When I got it, the transformer was tapped for 480 and I don't think that they where getting a full 480V (prob 450-460 at best) at the school so they battled low system voltage problems, because I've had none of the problems that they claimed to have.

So with that said.......this QT8 is happy about everything, no alarms, no errors on the drives, everything functions like a new machine...........except the spindle.

When I run the spindle manually, I have to be conservative on how fast I run it up or it'll make a plastic sounding clashing noise and it kicks out into sort of a neutral until I drop the RPM down some and it'll pick back up (this happens at the lower RPMS...below 1000), above 1000 the motor tone changes and it runs strong to 6k.

On automatic mode, the spindle will start but struggles to get up to 400 rpm and then stalls and just hangs out there..............keep in mind, no alarms tripped at all.

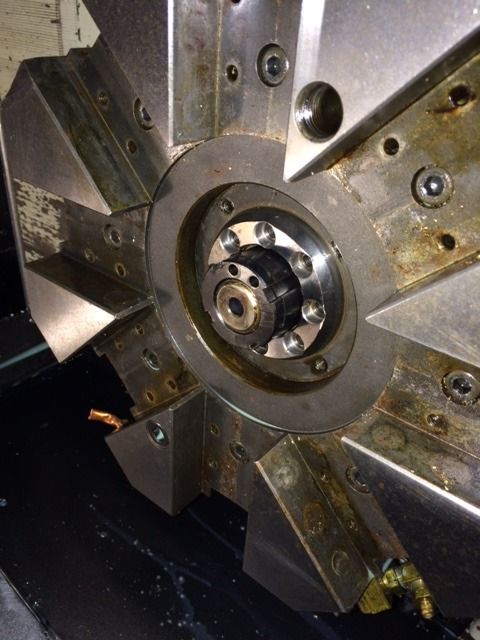

I have been all over this machine........checked all the parameters (including the hidden parameters), checked system power, check for voltage drop across all the contactors, checked ground, ohmed the spindle motor, loosened and retightened every electrical eyelet and unplugged and re-plugged all the connectors. Since the control is happy through out all this trouble I must conclude that there is an issue with the motor but my lack of knowledge on the Mazak drive systems has me asking for help understanding this gear change business. Is there a gearbox integrated into the headstock that I'm not seeing? Is it stuck in high gear? I see a Gear Change soft key on the display but I can't find anything about it in my manuals.

HELP!